Flooring/carpentry help

- Started

- Last post

- 26 Responses

- detritus0

I was going to suggest yanking them with pliers earlier, but bowed to greater noluj.

I particularly love that your completed scene includes a case of beer

'clink!

- terry_cloth0

- What would you suggest?eryx

- pulling it back off. ripping a clean line in the flooring underneath with a circ saw and making a flush transition to the flooringterry_cloth

- i would use my tracksaw for the cut though, basically a circ saw that runs on a jigterry_cloth

- It's floating floor there terry. How would you handle the expansion gap required with a flush fit?ETM

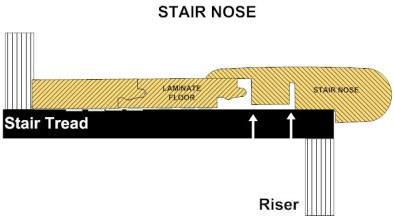

- These types stair nosings are designed specifically with that overlap to allow the gap, just like a t-mould would.ETM

- it's got gap to expand on the other 3 sides, if it separates a little bit over time between the nosing and the floor that's your trade off for not living with aterry_cloth

- trip hazard right in front of a stair. small price to pay imoterry_cloth

- also, the boards don't really expand length wise, this is more a case of cheap shit being installed cheaply than necessityterry_cloth

- You're applying how real wood expands vs mdf/hdf cores which expands evenly.ETM

- When a laminate floor is assembled it'll expand evenly in both directions, in proportion to it's dimensions.ETM

- well it's not going to heave length wise now is itterry_cloth

- nocomply0

@terry_cloth - Yeah the whole setup is more of less a lawsuit waiting to happen. My dad (a lawyer) suggested we put up a railing that separates the upper dining area from the sunken living room area, but that would just look hideous.

The step down is a lot greater of a danger than the lip of the cap piece. And since all of the flooring is the same color it's easy for people to miss the step. It's happened before. When we have parties or large gatherings I cover the top of the entire cap piece with blue painters tape to make it more visible.

Eventually my wife and I want to replace the flooring and raise the sunken living room, but considering the cost involved it's quite low on the list of priorities.

- split levels are not considered unsafe, plenty of people have them, it was quite a fad in residential architecture not too long ago. trip hazards are a differenterry_cloth

- -t issue. you have a large protuberance who's only function is to cover up shitty DIY workmanship on the finish edges of the flooringterry_cloth

- not a worth while trade off imoterry_cloth

- never mind that laminate hardwood flooring is packed with fucked up carcinogensterry_cloth

- terry_cloth0

- lolmonospaced

- look at the direction the flooring is going here. this is the context in which expansion is relevant. your boards go perpendicular to the fake nosing, you don'tterry_cloth

- need a gap for expansionterry_cloth

- *facepalm. You don't understand how mdf/hdf expands/contracts versus real wood.ETM

- do you really think the planks are going to heave and separate if they are perpendicular to what they are pressing up against. you tell me mr. mdfterry_cloth

- i think the worst that will happen is you will eventually have an 1/8th of an inch gap between the edge of the flooring and the nosingterry_cloth

- nocomply0

That diagram shows exactly what's going on. I don't deny that it's unsafe, but what would the alternative be?

- There really isn't one with floating floors like laminate.ETM

- When you redo it down the line, use real hardwood that is fastened to the sub-floor, then you can use proper, flush nosings/treads.ETM

- i agree but in the mean time there are safe solutions that wouldn't look terrible and would function well enough. safety first guysterry_cloth

- like i said, cut the ends of the boards into a nice straight line, cut down your riser, get a piece of hardwood nosing, rip it to the right length, drop that puterry_cloth

- -ppy in and deal with any gaps that open up as they appearterry_cloth

- "Deal with any gaps" how? You're solution is not viable for floating floors.ETM

- Is the overlap nosing undesirable... yes. Your solutions, however, will only cause new issues.ETM

- refer to the previous post. i explain why this is not an issueterry_cloth

- You're simply wrong on how laminate expands and contracts. It's glued sawdust, not real wood grain. I come from a family of trades and probably laid a footballETM

- field worth of this shit myself. Let alone engineered wood and both pre-finished and site finished hardwood.ETM

- You seem to think mdf expands like real wood grain, more across the grain then the length. But you don't know what you are talking about. You assembled theETM

- laminate planks into a square room, it'll expand and contract evenly in all 4 directions assuming a significant weight isn't pinning it down on one end.ETM

- You're giving advice against the nature of the product, without even seeing or knowing the site conditions in an attempt to look knowledgable and you're givingETM

- shit advice to a DIYer that could compromise his whole floor.ETM

- It he is concerned about the trip hazard, he should get a local flooring pro to evaluate the actual conditions/options.ETM

- you missed the point. the point is that the floating floor is not going to heave and bow if it's tight to a flush nosing perpendicularly. it may open up a littlterry_cloth

- e when it eventually contracts but it won't lift up because of itterry_cloth

- just because you have done something one way a million times doesn't mean you have a conceptual understanding sufficient to alter the procedure. think outside tterry_cloth

- he box for a second. his floor would not heave and be ruined, you are being melodramatic and acting like the way you were taught is some kind of dogmatic cannonterry_cloth

- neither or us has seen the site conditions but it's better to come up with a creative solution and ruin your cheap ass floor than leave a trip hazard. as far asterry_cloth

- you guessing my motivations, don't go there mr. mdf, i did real carpentry with real wood so don't lecture meterry_cloth

- *edit: potentially ruin your cheap ass floorterry_cloth

- *facepalmETM

- in your professional opinion can you tell me honestly that perpendicularly pressing against a tight fitting nosing will cause floor failure or just an eventualterry_cloth

- 1/8th inch gapterry_cloth

- If the short side locking mechanism of the planks is a 'drop to lock' style instead of 'angle to lock', you can have issues, even with the orientation ofETM

- the boards you highlight. It may be less likely than failure along the long side, but it can happen, especially since you have no idea what the expansion spaceETM

- is on the opposite side without seeing in person.ETM

- You assume the floor will contract, saying an eventual gap. Depending on season, location and humidity, the floor could instead expand that 1/8 to 1/4 inch.ETM

- I'm not hear defending the "quality" of laminate floors, just their realities.ETM

- *hear = hereETM

- fair enough. i'd take that over a 1?4 inch lip in front of my split level star, i can't imagine who would float a floor down an entire staircase, have you everterry_cloth

- installed one of those, is that doneterry_cloth

- Prefer to color match real wood treads, if possible. But when laminate is on a stairs, you use adhesive. You can't float that there. Death trap.ETM

- I would think soterry_cloth

- eryx1

- it's called padding out, yea, he could cleat and pad out and throw one of these on. i think this is a great solutionterry_cloth

- btw, the face already is level, he would just need to pad the cavity so there would be something for this jazz to sit onterry_cloth

- http://www.homedepot…eryx

- ^to big a gap for this?eryx

- haha, that's crazy. good old, regular 2x4 blocks chopped down into cleats every two feet would be more than enoughterry_cloth

- lol I guess if you want to do it the easy way.eryx

- plus, you would need like 8 bags of that to fill that chasm, you would then need to reinforce the structure to hold all that weight, then you would need to useterry_cloth

- a powder actuated ramset to fasten anything to it but yaknow, whatever worksterry_cloth

- Since self leveling cement is not very viscous by nature, it wouldn't have stayed in the void, regardless. It would run out and into everything via any gap.ETM

- anywaysterry_cloth